Cast Stone Products: Blending Timeless Aesthetics with Contemporary Performance

In the realm of architectural design and construction, the quest for materials that offer both enduring beauty and robust functionality is perpetual. Among the sophisticated solutions available, cast stone stands out as a remarkable material, seamlessly marrying the traditional aesthetics of natural cut stone with the advanced performance capabilities demanded by modern building practices. This elegant composite, often seen adorning stately homes and grand public buildings, provides an unparalleled versatility that allows designers and builders to achieve classic grandeur without compromising on contemporary structural integrity and efficiency. As projects increasingly prioritize durability, customization, and long-term value, cast stone emerges as an ideal choice, embodying a legacy of craftsmanship while embracing innovations in manufacturing and application.

Understanding the Enduring Appeal of Cast Stone

Cast stone has been revered for centuries as a material capable of replicating the exquisite appearance of natural quarried stone, including limestone, granite, and sandstone. Its ability to capture intricate details and replicate various textures has made it a preferred material for architects and builders aiming for a sophisticated, classic aesthetic.

What Defines Cast Stone?

Cast stone is a highly refined architectural precast concrete building material, manufactured from a carefully controlled mixture of cement, natural aggregates, manufactured sand, water, and often chemical admixtures to enhance workability and performance. This precise composition allows it to achieve the look and feel of natural cut stone, offering a consistent quality and finish that is difficult to attain with quarried materials. Unlike ordinary concrete, cast stone undergoes a rigorous casting process, often employing wet-cast or dry-tamp methods, to produce dense, durable, and highly detailed elements. The result is a product with a refined finish and consistent color, designed to withstand the test of time and weather, often exceeding the performance characteristics of many natural stones.

A Legacy of Grandeur: Traditional Aesthetics

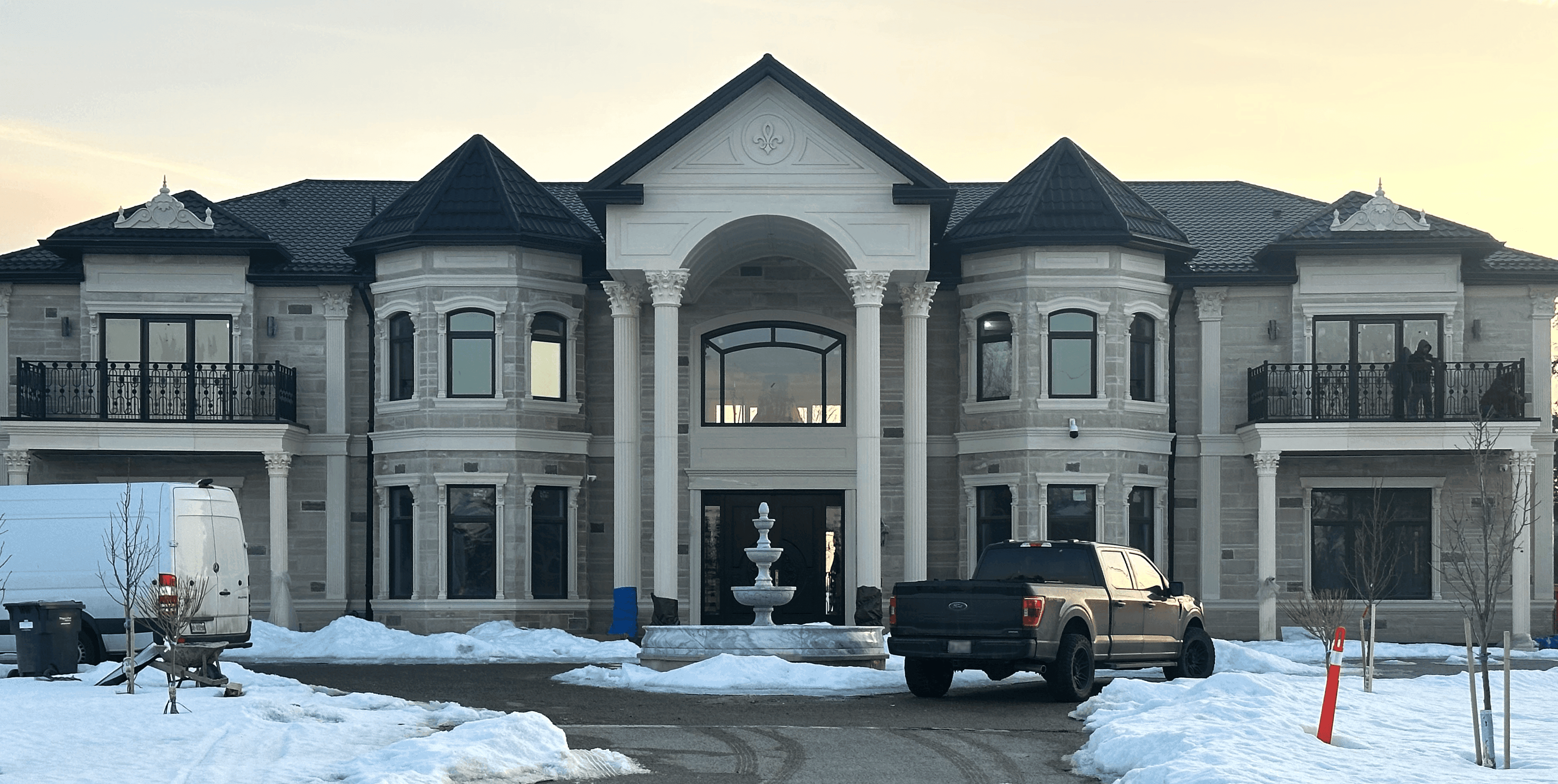

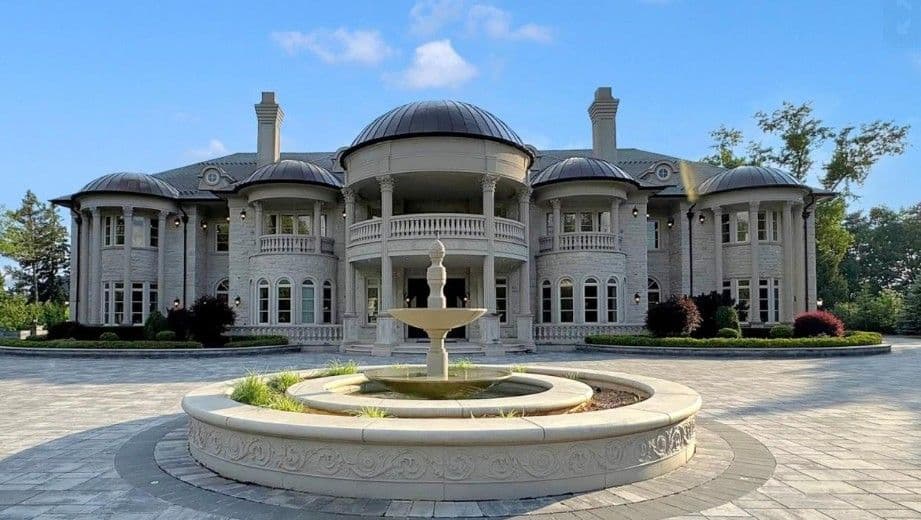

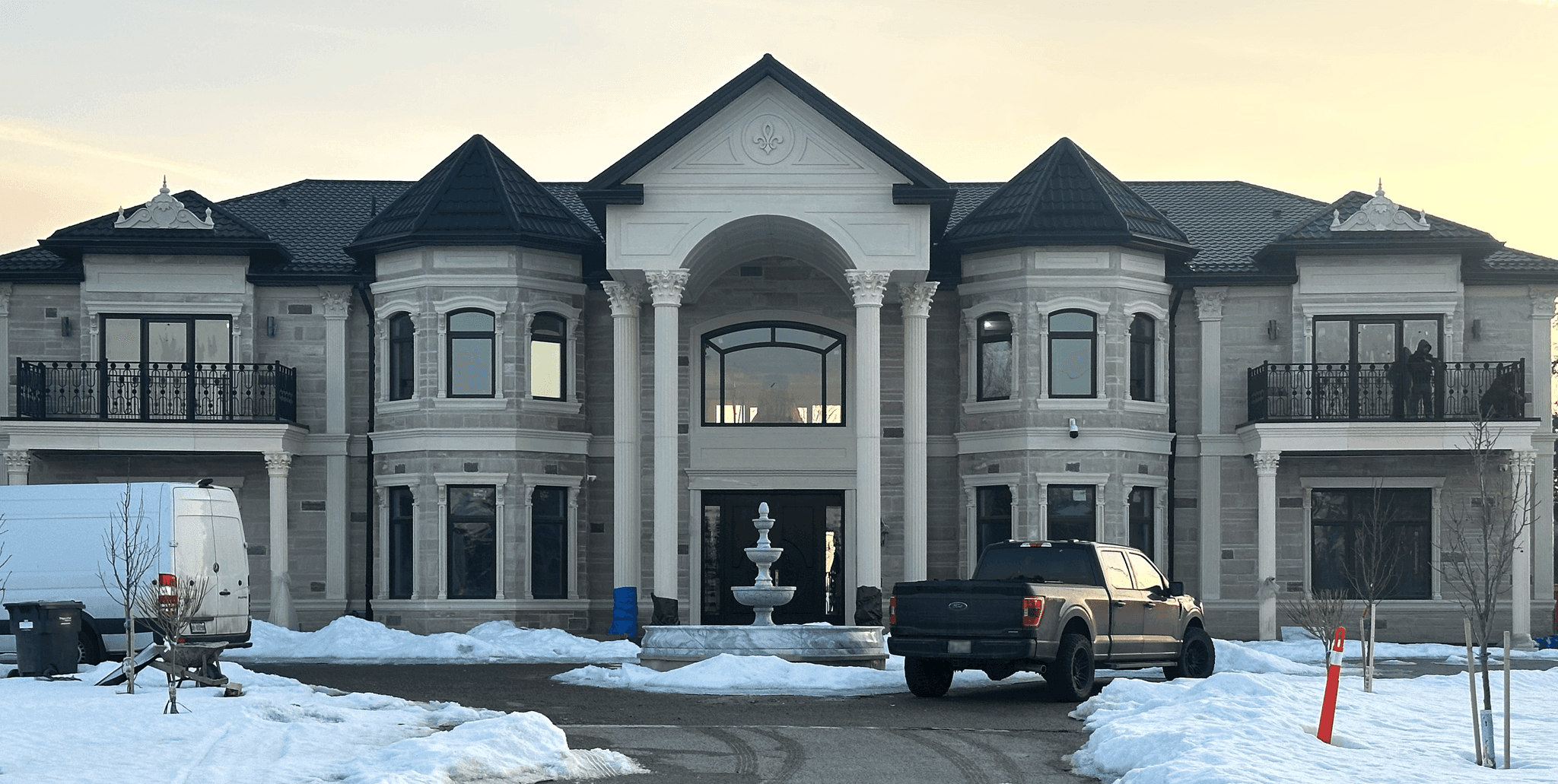

The traditional appeal of cast stone lies in its capacity to evoke a sense of history, permanence, and luxury. Historically, natural stone was the material of choice for monumental structures, signifying wealth and prestige. Cast stone provides an accessible alternative that faithfully reproduces the grandeur and intricate detailing found in traditional masonry. From grand architectural cast stone facades to elaborate balustrade systems, columns, and ornate cornices, cast stone elements have long been integral to creating structures with timeless elegance. Its ability to be molded into virtually any shape or size means that bespoke architectural details, once laboriously hand-carved from natural stone, can now be replicated with precision and consistency, maintaining the classic masonry looks that define enduring design. This makes it particularly valuable for new construction aiming for a heritage aesthetic, as well as for authentic restoration projects where matching existing precast concrete or natural stone elements is crucial.

Modern Performance: Durability, Versatility, and Efficiency

While its aesthetic lineage is firmly rooted in tradition, cast stone’s modern performance characteristics make it a superior choice for contemporary construction, addressing critical factors like longevity, design flexibility, and cost-effectiveness.

Exceptional Durability and Longevity

Modern cast stone products are engineered for outstanding durability, offering a long-lasting architectural element that withstands the rigors of weather and time. The controlled manufacturing environment ensures a consistent, high-strength product with low porosity, making it highly resistant to moisture penetration, freeze-thaw cycles, and general weathering. This inherent resilience means that cast stone elements retain their beauty and structural integrity for decades, often outperforming many types of natural stone that can be prone to cracking, spalling, or erosion over time. Its robustness contributes to reduced maintenance requirements and lower lifecycle costs for buildings, providing a sustainable and economical solution for long-term architectural investments. This emphasis on durable precast concrete solutions is a key driver in the modern construction sector, aligning with demands for resilient and sustainable building practices.

Unparalleled Design Flexibility and Customization

One of cast stone’s most significant advantages in modern applications is its extraordinary design flexibility and customization capabilities. Unlike natural stone, which is limited by quarry yields and the inherent properties of the stone block, cast stone can be molded into virtually any form, texture, or color. This allows for the creation of intricate custom cast stone architectural details, complex geometric shapes, and sculptural forms that would be prohibitively expensive or impossible to achieve with quarried stone. The ability to specify precast concrete color options and a wide range of precast concrete finishes and textures—from smooth ashlar to rugged rock-faced, or finishes mimicking acid wash and traditional precast—provides architects and designers with unparalleled creative freedom. This bespoke approach ensures that every project can have truly unique, tailored solutions, appealing to discerning clients who prioritize distinctive aesthetics and precise specifications for their custom architectural precast needs.

Precision Manufacturing for Consistent Quality

The modern manufacturing process of cast stone involves advanced techniques and rigorous quality control, resulting in a product of consistent quality and dimensional accuracy. Unlike the variability often found in natural stone, each cast stone element can be produced to exact specifications, ensuring perfect alignment and fit during installation. This precision not only streamlines the construction process but also contributes to the overall structural integrity and aesthetic harmony of the building. The controlled environment of a manufacturing facility allows for meticulous attention to mix designs, curing processes, and finishing, which are critical for achieving optimal strength, color uniformity, and surface quality. This consistency minimizes on-site adjustments and waste, contributing to greater efficiency and predictability in project timelines and budgets.

Diverse Applications: Enhancing Every Architectural Vision

The versatility of cast stone allows for its application across a wide spectrum of architectural and decorative elements, making it suitable for both grand commercial projects and sophisticated residential designs.

Architectural Building Elements

Cast stone is extensively used for creating foundational and decorative building architectural elements that define a structure's character and elegance. This includes the stately presence of precast concrete columns, which can be custom made to various diameters and heights, serving as both structural supports and decorative features. Ornate precast concrete cornices add classic detailing to rooflines and facades, providing a refined transition between building planes. Complex precast concrete balustrade systems offer safety and aesthetic appeal to balconies, staircases, and terraces, with intricate designs that enhance the overall architectural language. Beyond these, the material is also used for robust precast concrete wall panels, offering both aesthetic appeal and efficient construction solutions.

Enhancing Facades and Openings

The exterior of a building is its first impression, and cast stone excels at creating striking facade and opening elements. Window and door surrounds, meticulously crafted from cast stone, frame openings with depth and character, elevating mundane entryways into statements of sophistication. Quoins, decorative cornerstones often found on historical buildings, can be easily replicated in cast stone, adding architectural articulation and a sense of permanence. Coping stones provide a protective and aesthetic finish to parapet walls, chimneys, and garden walls, ensuring durability while maintaining visual appeal. Furthermore, precast concrete pier caps provide a refined finish to gate posts and columns, completing the aesthetic harmony of entrance features.

Landscape and Decorative Features

Beyond the building itself, cast stone extends its aesthetic and durable qualities to outdoor and landscape elements. Precast concrete fountains serve as elegant centerpieces in gardens and courtyards, offering intricate designs that stand up to the elements. Precast concrete planters introduce classical or contemporary flair to outdoor spaces, providing durable and attractive containers for greenery. Precast concrete benches offer comfortable and stylish seating, integrating seamlessly into garden designs or public spaces. These outdoor concrete fountains and precast garden elements not only enhance the visual appeal of a landscape but also offer a low-maintenance, long-lasting alternative to other materials, capable of withstanding diverse climatic conditions.

Restoration and Replication Projects

The unique ability of cast stone to mimic natural stone makes it an indispensable material for restoration projects. For historic building restoration, cast stone can be meticulously manufactured to match existing precast concrete elements or historical stone, ensuring architectural authenticity and material consistency. This includes intricate facade restoration services, where damaged or missing elements are replaced with newly cast pieces that seamlessly integrate with the original structure. The capacity for custom design finishes and color matching is particularly valuable in these applications, allowing for precise replication of original architectural details, preserving the historical integrity and aesthetic continuity of heritage buildings.

Cast Stone vs. Natural Stone: A Strategic Comparison

While natural stone possesses an undeniable inherent beauty, cast stone offers compelling advantages that often make it the more practical and strategic choice for modern construction and design.

Aesthetic Parity with Superior Consistency

Cast stone is specifically designed to replicate the aesthetic appeal of natural stone. Modern manufacturing techniques allow for highly sophisticated textures and color variations that closely mimic limestone, sandstone, and other desirable quarried materials. However, unlike natural stone, which can exhibit unpredictable variations in color, veining, and structural integrity due to geological processes, cast stone offers unparalleled consistency. This means that an entire order of cast stone elements will maintain a uniform appearance, ensuring a cohesive and harmonious look across a large project. This consistency is a significant advantage for large-scale architectural endeavors where uniformity is paramount, eliminating the need for extensive sorting or selection often required with natural stone.

Cost-Effectiveness and Predictable Lead Times

From a project management perspective, cast stone often provides significant cost advantages over natural stone. The quarrying, cutting, and shaping of natural stone can be labor-intensive and expensive, particularly for custom or intricate designs. Cast stone, being a manufactured product, can be produced more efficiently and at a lower cost per square foot, especially when creating multiple identical pieces. Furthermore, the fabrication of cast stone typically adheres to more predictable lead times compared to natural stone, which can be subject to quarry availability, weather conditions impacting extraction, and complex transportation logistics. This predictability in both cost and schedule is invaluable for builders and developers seeking to maintain project budgets and timelines, streamlining the overall construction process.

Enhanced Performance Characteristics

Beyond aesthetics and cost, cast stone often surpasses natural stone in specific performance metrics. Engineered for durability, cast stone can achieve superior compressive strengths and lower absorption rates than many types of natural stone, making it more resistant to erosion, staining, and the damaging effects of harsh weather. For elements like precast concrete fireplace surrounds, cast stone offers a reliable and fire-resistant solution, providing the warmth and character of stone without the inherent vulnerabilities of some natural variants. Its controlled composition also allows for the integration of features like reinforcement, which can enhance structural integrity beyond what is possible with a single block of natural stone, contributing to its long-term resilience and a lower maintenance profile.

The Crucial Role of Expert Craftsmanship and Technology

The successful integration of cast stone into any project hinges on a combination of skilled craftsmanship and advanced manufacturing technology, ensuring that traditional aesthetics are perfectly executed with modern precision.

From Design to Installation: A Comprehensive Approach

The journey of cast stone from concept to completion requires a comprehensive approach, encompassing expert precast concrete design, precise custom precast fabrication, and meticulous precast concrete installation. Experienced manufacturers work closely with architects and designers to transform initial visions into detailed drawings, leveraging their knowledge of material capabilities and structural requirements. This collaborative design phase is critical for ensuring that the aesthetic goals align with the practical realities of production and installation. Following design approval, the fabrication process employs specialized molds and casting techniques to achieve the desired forms, textures, and finishes. Finally, professional precast concrete installation teams ensure that each element is correctly positioned and secured, guaranteeing both the structural integrity and the visual perfection of the finished work. This holistic service offering, from conceptualization to final placement, provides clients with a seamless and reliable experience.

Upholding Quality Assurance and Certifications

In an industry where trust and reliability are paramount, quality assurance and industry certifications are non-negotiable. Reputable cast stone manufacturers adhere to stringent quality control protocols at every stage of production, from material sourcing to final curing. This commitment ensures that all products meet or exceed established industry standards for strength, durability, and appearance. Certifications from recognized bodies, such as the CSA (Canadian Standards Association) or PCI (Precast/Prestressed Concrete Institute) where applicable, serve as independent verification of a manufacturer's adherence to best practices and quality benchmarks. Clients seeking experienced GFRC manufacturers or quality precast suppliers should always look for these credentials, as they signify a commitment to excellence and a proven track record of delivering superior products. This dedication to quality not only ensures project success but also builds long-term confidence with clients and stakeholders.

Choosing the Right Partner for Your Cast Stone Project

Selecting a knowledgeable and experienced partner is vital for any cast stone project, ensuring that the inherent beauty and performance of the material are fully realized. A partner with deep material expertise, a commitment to customization, and a clear understanding of regional needs can transform architectural visions into enduring realities.

Expertise in Material Science

The true value of cast stone lies in its precise composition and manufacturing. A leading provider of cast stone products possesses extensive expertise in the material science behind advanced concrete composites. This includes a thorough understanding of aggregates, admixtures, and curing processes that optimize strength, density, color consistency, and weather resistance. Such specialized knowledge ensures that the cast stone supplied is not merely aesthetically pleasing but also engineered for superior performance and longevity, standing up to the specific demands of any environment.

A Commitment to Customization and Design Excellence

For architects and designers, the ability to bring unique visions to life is paramount. A proficient cast stone partner distinguishes itself through a profound commitment to customization. This means offering not just a range of standard products, but the capability to custom make any design or match any existing color or finish for any restoration project. This focus on bespoke solutions allows for unparalleled design freedom, ensuring that every architectural detail, from elaborate precast concrete columns to unique wall panels, precisely reflects the project's artistic and functional requirements. Such a partner thrives on challenging projects, transforming complex design concepts into tangible, high-quality cast stone elements.

Local Service with Broad Reach

While a strong local presence is beneficial for direct consultation and project oversight, a truly comprehensive partner offers broader capabilities. For instance, a company well-established in the Greater Toronto Area, serving cities like Precast concrete Toronto, Precast concrete Mississauga, Precast concrete Hamilton, and Precast concrete Oakville, also demonstrates the capacity for wider shipping services across Precast concrete Canada and the USA. This tiered geographic approach allows for the efficient handling of local projects while simultaneously catering to specialized or custom architectural precast needs on a national or even cross-border scale. This dual capability ensures that clients, regardless of their location, have access to premium cast stone solutions and expert support.

Conclusion

Cast stone represents a remarkable synthesis of timeless elegance and contemporary engineering. It offers the classic, distinguished aesthetics of natural stone while delivering superior durability, unparalleled design flexibility, and consistent quality through modern manufacturing processes. From intricate architectural elements that define grand facades to robust landscape features that enhance outdoor spaces, cast stone products provide a versatile and high-performance solution for discerning architects, builders, and designers. Its ability to achieve historical authenticity for restoration projects and custom designs for new constructions makes it an invaluable material in the construction industry. By choosing cast stone, projects gain a material that is not only visually stunning but also built to endure, delivering lasting value and beauty for generations.

Elevate Your Vision with Expert Cast Stone Solutions

Are you planning an architectural project that demands the timeless beauty of stone combined with modern performance and customization? Explore the vast potential of cast stone products for your next endeavor. Contact us today to discuss your specific requirements, receive a custom cast stone quote, or learn more about how our precision-engineered solutions can bring your most ambitious designs to life. Let us help you blend traditional aesthetics with contemporary performance to create enduring architectural masterpieces.

More Blogs

Precast

September 8, 2025

Architectural Precast Panels: Transforming Commercial Building Design in Canada

Architectural precast panels represent custom-designed concrete elements manufactured in controlled factory environments specifically to serve as buil...

Architecture

September 8, 2025

Custom Cast Stone vs. Natural Stone: Which is Right for Your Architectural Project?

Compare custom cast stone & natural stone for architectural projects. Learn about their aesthetics, performance, cost, and installation to make an inf...

GFRC

September 8, 2025

Custom GFRC: Bringing Architectural Visions to Life Through Bespoke Lightweight Concrete Solutions

Discover custom GFRC's power to bring architectural visions to life. Lightweight, strong, durable, and highly flexible, it enables unique, bespoke des...