Architectural Precast Panels: Transforming Commercial Building Design in Canada

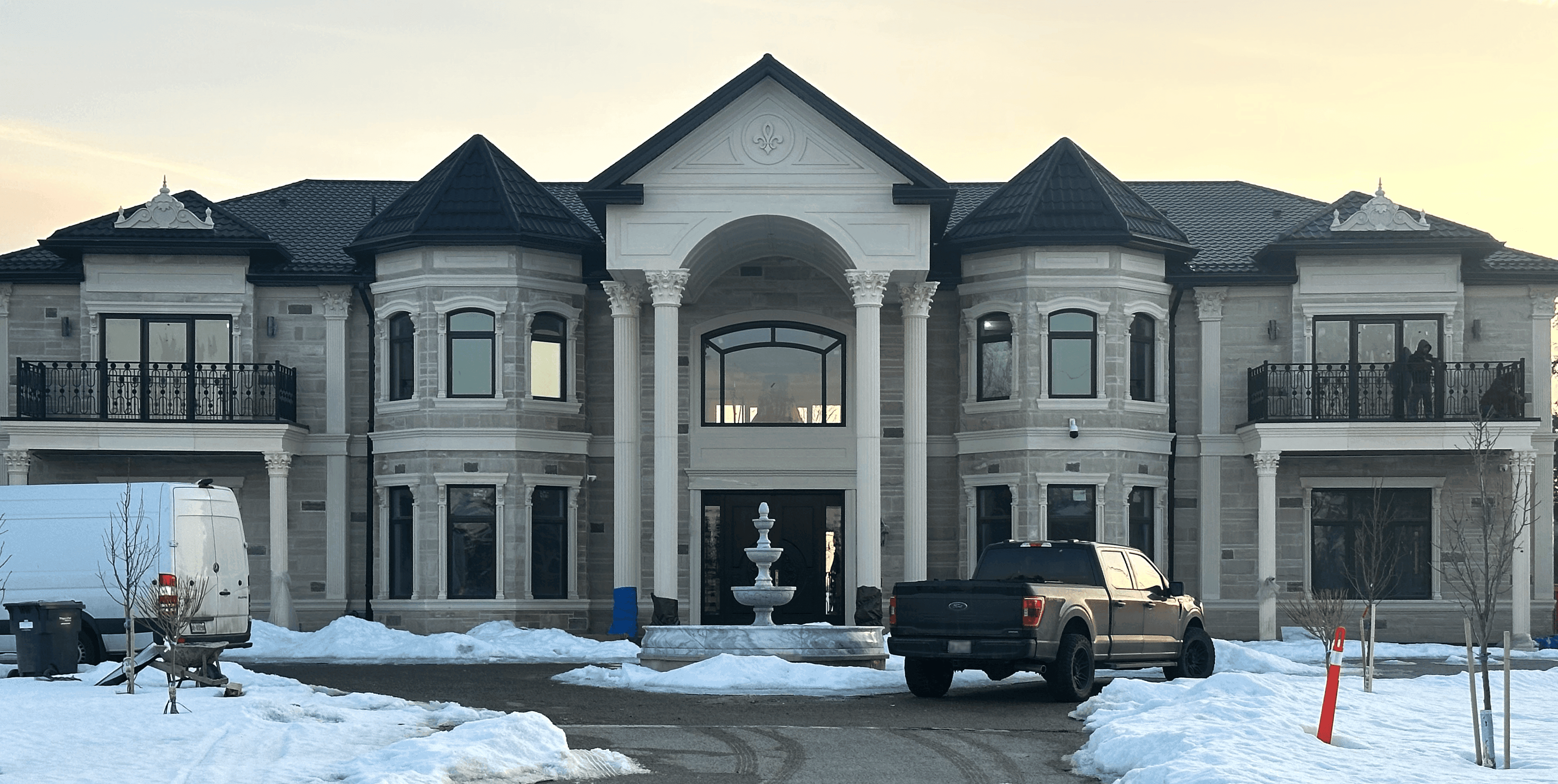

In Canada's competitive commercial architecture landscape, where striking first impressions and exceptional durability define success, architectural precast panels have emerged as the premier facade solution. These precision-engineered concrete elements seamlessly blend aesthetic versatility with structural integrity, enabling architects and developers to create iconic buildings that withstand decades of Canadian weather conditions. At Petra Design, with over 25 years of manufacturing expertise, we specialise in delivering premium architectural precast panels, including advanced UHPC exterior cladding and insulated precast concrete panels, to projects across Canada, the USA, and international markets.

Understanding Architectural Precast Panels

Architectural precast panels represent custom-designed concrete elements manufactured in controlled factory environments specifically to serve as building exteriors. Unlike structural precast components focused primarily on load-bearing capabilities, these panels function as sophisticated facade systems that provide both exceptional aesthetic appeal and comprehensive weather protection.

These non-load-bearing elements attach to structural frameworks rather than supporting building weight, yet contribute significantly to overall building performance through thermal insulation, weather resistance, and sound attenuation properties. The controlled manufacturing process enables extraordinary precision in dimensions, textures, colours, and finishes, transforming each panel into a bespoke architectural element that realises design visions with remarkable accuracy.

Key characteristics include unlimited customisation possibilities allowing panels to be cast in virtually any shape, size, and configuration for complex architectural designs. Aesthetic versatility encompasses extensive finish options from smooth polished surfaces to exposed aggregates, intricate patterns, and simulated natural materials. Inherent durability provides strength and resistance to harsh weather, fire, and seismic activity, while manufacturing efficiency enables factory production and rapid installation that significantly reduces construction timelines.

Precision Manufacturing Excellence

Creating architectural precast panels demands precision engineering and advanced manufacturing techniques within controlled plant environments that ensure consistent quality, superior finishes, and exact adherence to design specifications that prove challenging with traditional on-site construction methods.

The process begins with detailed architectural and structural designs utilising computer-aided design and building information modelling to create precise moulds and panel layouts ensuring seamless structural integration. Custom moulds are fabricated to exact panel specifications using materials ranging from timber and steel for standard shapes to fibreglass and rubber for complex curves and intricate details, with mould quality directly impacting final panel finish.

Steel reinforcement placement provides essential tensile strength while lifting inserts, connection points, and necessary openings for windows or doors are meticulously positioned. Specialised concrete mix designs achieve desired strength, durability, and aesthetic qualities through specific aggregates for colour and texture, plus admixtures enhancing workability, strength, and weather resistance. For UHPC exterior cladding applications, unique mixes incorporating ultra-fine aggregates and high-performance binders deliver exceptional performance characteristics.

Careful casting and consolidation eliminate air voids through vibration techniques ensuring full compaction and bringing fine aggregates and cement paste to surfaces, which proves crucial for achieving high-quality architectural finishes. Controlled curing processes involving steam or radiant heat accelerate strength development while ensuring optimal hydration, minimising shrinkage and cracking for enhanced long-term durability.

After curing and demoulding, extensive finishing options become available including smooth acid-etched surfaces for clean uniform appearance, exposed aggregate finishes revealing natural aggregate beauty, sandblasted or bush-hammered textures creating rugged surfaces, formliner textures imparting patterns like wood grain or custom designs, and polished or honed finishes for refined glossy or matte appearances.

Elevating Commercial Design Possibilities

The widespread adoption of architectural precast panels in Canadian commercial projects stems from their unparalleled aesthetic versatility that liberates architects from traditional material constraints, providing limitless creative possibilities through concrete's adaptability as an architectural medium.

Colour and texture control through concrete mix manipulation, aggregate selection, and surface treatments enables extensive palettes from natural concrete grays to vibrant pigmented hues, spanning ultra-smooth polished surfaces to rugged exposed aggregate finishes that can mimic natural stone, brick, or create entirely unique visual effects perfectly complementing building design intent and surrounding environments.

Form and shape capabilities allow casting into virtually any conceivable configuration including complex curves, intricate geometric patterns, and large monolithic forms. This design freedom enables architects to realise ambitious visions difficult or impossible with other materials, while factory production precision ensures complex shapes fit together seamlessly during installation.

Integrated elements reduce multiple trade requirements while enhancing overall quality through pre-formed window and door openings ensuring precise fit and finish, embedded materials like brick, natural stone, or tile cast directly into panels creating composite facades combining precast benefits with desired aesthetics, and relief plus sculptural elements through custom moulds enabling intricate patterns, logos, or full GFRC sculptures integral to panel design.

Performance and Durability Advantages

Beyond exceptional aesthetics, architectural precast panels deliver significant long-term advantages in durability, performance, and sustainability that make them strategic investments for commercial projects requiring decades of reliable service.

Factory curing processes optimise concrete strength creating panels highly resistant to rain, wind, snow, and extreme temperature fluctuations common in Canadian climates. Fire resistance through concrete's non-combustible properties provides excellent building safety contributions, while properly designed and connected precast panels perform exceptionally during seismic events. The dense, durable concrete surface requires minimal maintenance throughout its lifespan, substantially reducing operational costs.

Thermal performance contributes significantly to building energy efficiency, particularly through insulated precast concrete panels that incorporate rigid insulation layers creating continuous thermal barriers. This eliminates thermal bridging while substantially improving building R-values, leading to considerable energy savings and enhanced indoor comfort. Concrete's inherent thermal mass helps regulate indoor temperatures, reducing heating and cooling loads, while precise manufacturing and installation contribute to highly airtight building envelopes further reducing energy loss.

Sound attenuation through concrete density provides excellent acoustic insulation, making precast panels ideal for buildings in noisy urban environments or spaces requiring acoustic privacy like hospitals, schools, and offices. Sustainability credentials align with green building initiatives through factory production minimising on-site waste with recyclable excess materials, precast mixes incorporating recycled aggregates and supplementary cementitious materials, local material sourcing reducing transportation emissions, and extended structural lifespans conserving resources over time.

Commercial Applications Across Canada

Architectural precast panels demonstrate remarkable versatility across diverse commercial and large-scale residential projects throughout Canadian markets, each benefiting from unique precast advantages tailored to specific building requirements.

Office buildings and corporate campuses favour precast panels for creating sophisticated, professional facades that offer rapid building enclosure allowing interior work to commence sooner, while exceptional durability ensures long-lasting, low-maintenance exteriors that maintain corporate image standards throughout decades of service.

Healthcare facilities benefit from precast construction speed, inherent fire resistance, and ability to create clean, durable surfaces meeting stringent healthcare standards while providing quiet, healing environments for patients and staff through superior acoustic performance.

Educational institutions utilise precast for exceptional robustness, sound attenuation properties, and capabilities for creating inviting, inspiring learning environments with diverse architectural expressions that stimulate creativity while providing safe, durable structures for generations of students.

Retail and mixed-use developments leverage precast panels for attractive, durable facade solutions often incorporating intricate designs and integrated signage that creates distinctive brand identities while withstanding heavy foot traffic and urban environmental challenges.

Multi-family residential buildings increasingly specify precast concrete wall panels for rapid erection capabilities, superior fire safety, excellent sound insulation between units, and aesthetic flexibility offering residents high-quality living environments in urban density developments.

Petra Design: Your Architectural Precast Partner

Our comprehensive expertise encompasses custom design and manufacturing capabilities working closely with architects and designers to transform visions into reality, producing bespoke panels with precise dimensions, intricate details, and extensive finish options. Factory-controlled environments ensure every panel meets exceptional standards for strength, durability, and aesthetic quality through rigorous quality assurance protocols.

Efficient supply and delivery coordination ensures timely, safe panel delivery to project sites, contributing to accelerated construction schedules and reduced overall project costs. Technical support teams provide expert guidance throughout project lifecycles, ensuring optimal performance and installation success while maximising long-term building performance.

Choosing Petra Design means partnering with Canada's architectural manufacturing leader, dedicated to delivering innovative, durable, and visually stunning precast solutions that elevate commercial projects while providing exceptional value through superior performance and longevity.

The Future of Commercial Building Design

Architectural precast panels represent more than building materials; they embody the fusion of engineering precision with artistic expression that defines contemporary Canadian architecture. Their exceptional design flexibility, superior durability, and significant construction efficiencies establish them as indispensable components for modern architects and developers creating landmark structures.

From enhancing commercial building aesthetic appeal to providing robust, energy-efficient building envelopes, precast concrete wall panels offer comprehensive solutions for today's construction challenges. As demand grows for high-performance, sustainable, and visually striking structures, architectural precast panels will continue gaining prominence in Canadian commercial construction.

Petra Design stands ready as your trusted partner, transforming architectural visions into enduring realities through our unwavering commitment to quality, innovation, and unparalleled craftsmanship that defines excellence in Canadian architectural manufacturing.

More Blogs

Cast Stone

September 8, 2025

Cast Stone Products: Blending Timeless Aesthetics with Contemporary Performance

Cast stone blends timeless aesthetics with modern performance, offering superior durability, versatility, and cost-effectiveness for all architectural...

Architecture

September 8, 2025

Custom Cast Stone vs. Natural Stone: Which is Right for Your Architectural Project?

Compare custom cast stone & natural stone for architectural projects. Learn about their aesthetics, performance, cost, and installation to make an inf...

GFRC

September 8, 2025

Custom GFRC: Bringing Architectural Visions to Life Through Bespoke Lightweight Concrete Solutions

Discover custom GFRC's power to bring architectural visions to life. Lightweight, strong, durable, and highly flexible, it enables unique, bespoke des...